BDO Annual Waste Report for 2024 - what do you need to know about the report on waste generated and waste management?

The beginning of the year also marks the beginning of the reporting period, in which entrepreneurs registered with BDO and keeping waste records must submit reports for 2024. Below we have collected the most important information and answers to the most frequently asked questions about BDO waste reports.

By when is the BDO waste report for 2024 submitted?

The annual report on waste generation and waste management must be submitted by 15 March for the previous calendar year. However, the deadline for submitting BDO reports for 2024 is 17 March 2025. Why March 17 and not March 15? In 2025 March 15 falls on a Saturday, therefore, by operation of law, the deadline for submitting the BDO report is postponed to the next business day, i.e. Monday, March 17.

This of course applies to entrepreneurs who continue to operate. Entrepreneurs who close their company are required to submit a report within 7 days of closing their business.

Who should submit the BDO annual waste report for 2024?

The annual BDO report, technically known as the annual report on waste generation and waste management, for 2024 is required to be submitted by all entities that :

- in 2024 they were subject to the obligation to keep waste records in the BDO (produced or managed waste),

- in 2024, as part of their activities, extracted waste from a landfill or waste dump on the basis of a consent to extract waste or a decision approving the instructions for running a waste landfill in the post-operational phase.

We would like to remind you that the obligation to submit an annual report also applies to entities keeping simplified waste records in BDO!

Don't have a BDO number? Check if you are obliged to register with BDO!

Is it necessary to submit a zero BDO waste report for 2024?

Entities that did not produce or process waste in 2024 are not required to submit a zero report .

How to submit a BDO waste report for 2024?

An annual report on waste produced and waste management should be submitted to the voivodeship marshal appropriate for the place of production, collection or processing of waste . If you produce, process or collect waste in several voivodeships, you are obliged to submit reports to the voivodeship marshals in all voivodeships where you conduct this activity.

The report can be completed and submitted exclusively electronically , through an individual account in the BDO system. Each entrepreneur can do it on their own or entrust their duty to Interzero experts, gaining a guarantee of efficient, reliable and timely preparation and then submission of reports. Contact us and receive the best offer for taking over the BDO reporting obligation!

What should the BDO waste report for 2024 include?

Depending on the areas of activity of a given entity, the annual report on waste generation and waste management for 2024 may contain information on :

- mass and types of waste ,

- method of waste management (applies only to waste management entities),

- installations and devices used to process this waste, including technical data of machines and information on the functioning of installations and devices: number of working hours per day, dates and duration of failures or downtimes (applies only to entities processing waste),

- the amount of sulphates or chlorides in waste per Mg of titanium dioxide produced (applies to entities possessing or processing waste from titanium dioxide production processes),

- mass and types of food waste generated.

As a rule, yes. If you have not submitted a BDO report on time, you should do so immediately , without waiting for a possible inspection or summons from the office. Thanks to this, you have a chance to avoid a severe financial penalty. Interzero experts will help you settle all reporting arrears. Contact us and present your situation, and we will help you identify all outstanding obligations and complete the necessary formalities.

Remember that your company's reporting obligations expire after 5 years! This means that the office may call you to submit a report for up to 5 years back, and additionally impose a fine of up to PLN 5,000 on your company.

What is chemical recycling?

What is chemical recycling?

Chemical recycling, also known as raw material recycling, is a waste processing method that uses high temperature or chemical agents. Experts see it as a chance to manage contaminated and heterogeneous fractions that cannot be recovered using mechanical recycling methods.

Chemical recycling will allow the recovery of raw materials from contaminated waste fractions

Raw material recycling involves thermal decomposition of waste, which can yield liquid hydrocarbons or gases that are components for the production of new raw materials. It is used to process some plastics (e.g. PET, polyethylene, polypropylene). This type of recycling is more energy-intensive and more expensive than material recycling , shoe it allows for the return to circulation of waste that is heavily contaminated or heterogeneous (and therefore unsuitable for material recycling).

According to experts, chemical recycling should be a complement to mechanical recycling, which is currently used to process approximately 80% of plastics. Managing Director of the Plastics Europe Polska Foundation, Dr. Anna Kozera-Szałkowska, sees it as an opportunity to recycle raw materials that can be used for contact with food or in medical applications [i] .

[i] Zero recycling point in Poland , https://portalkomunalny.pl/wp-content/uploads/2024/12/raport-punkt-zero-recyklingu-w-polsce.pdf

How is chemical recycling done? Methods and applications

In the chemical recycling process, two basic reactions are used: breaking and creating new chemical bonds. This means that a plastic particle (polymer) is broken into smaller particles (including monomers), from which new polymers can be produced in the next stage . In this way, materials with identical properties to primary materials obtained from crude oil are obtained.

The most important technologies used during the chemical recycling process are:

- pyrolysis - thermal decomposition occurring without access to oxygen. As a result, pyrolysis oil is produced, from which, after purification and specialist processing, ethylene and propylene can be obtained, i.e. monomers that are the basic raw materials for the production of polyethylene and polypropylene,

- gasification - thermal decomposition occurring in the presence of oxygen. Almost all plastics can be processed in this process,

- solvolysis - an exchange reaction between polymer and solvent molecules. It is mainly used for processing PET.

Pyrolysis and gasification, however, do not fall within the statutory definition of recycling - the materials obtained in these processes are sometimes used as fuel. Therefore, energy is "only" recovered, which cannot be considered recycling. Nevertheless, pyrolysis is a promising method that can produce polymers with properties identical to those of the original polymers.

Chemical recycling of plastics is a necessity, not an option

Chemical recycling is not currently used on a large scale . The Plastics Europe publication [i] indicates that in 2023, only 0.12 million tonnes of plastics will be produced in Europe in this process. However, many experts believe that this method should, and even must, be popularised , especially in the context of the constant pursuit of increasing plastic recycling levels. As emphasized by Dr. Eng. Anna Kozera-Szałkowska, the sanctioning of chemical recycling technology is also necessary due to the upcoming legal regulations regarding the increase in the content of recyclates in consumer packaging. [ii]..

At Interzero, we understand these needs perfectly and have long been taking action to increase the scale of chemical recycling and at the same time reduce the mass of raw materials going to thermal recycling, i.e. waste incinerators. For this purpose, we have developed a special process for sorting mixed plastics, which until now were sent to incineration. In our method, waste is not sorted into monomaterials, but into streams precisely adapted to the requirements of chemical recycling.

In 2023, together with OMV, we started building the largest plastic waste sorting plant , which will then be sent to chemical recycling. The new Interzero and OMV investment, which will be put into operation as early as 2026, will have a processing capacity of up to 260,000 mixed plastics per year.

Discover all Interzero's chemical recycling initiatives.

[i] Plastics Europe, Plastics - Facts 2024 in a nutshell , https://plasticseurope.org/pl/knowledge-hub/tworzywa-fakty-w-pigulce-2024/

[ii]. Zero recycling point in Poland , https://portalkomunalny.pl/wp-content/uploads/2024/12/raport-punkt-zero-recyklingu-w-polsce.pdf

Invitation to Webinar: "Environmental obligations for companies selling to Poland - everything you need to know".

Does your company sell products to Poland? And do you know what environmental responsibilities this entails? Take part in a free webinar in English!

Why attend a webinar?

During the webinar we will discuss:

- Environmental obligations in Polish law - introduction

- Explanation of Extended Producer Responsibility (EPR)

- Licensing obligation for dealers and manufacturers

- The role of the authorised representative

- Good practices and support for companies

- Question and answer session

The meeting will be chaired by Przemyslaw Kuna, Managing Director of Interzero.

How to join a meeting?

To attend the webinar, simply register at HERE.

Registration is open until 20 February at 8am.

Trends in sustainability - what and how much are companies investing in? Survey report

The transition to a circular economy is inevitable - these are the conclusions of the latest Interzero study Businesses in the circular economy: a detailed analysis. The green transformation of companies is not only enforced by legislation. It is also expected by customers, investors and financial institutions. The best way to set the right course for change is to work with an environmental consultancy.

Sustainability as a to be or not to be for most entrepreneurs

From the survey Businesses in the circular economy: a detailed analysis shows that a significant Most companies want to implement sustainable initiatives or have already started doing sos. Such declarations were made by 71.1 to 84.9% managers representing medium and large companies from 6 European countries.

Companies in the FMCG (81%) and electronics (82%) sectors stand out as the most active in this respect. For this group of companies, the implementation of circular solutions is no longer considered in the context of competitive advantage - the it becomes necessary in order to maintain its current position on the market.

The situation is slightly different for companies in the construction, retail and logistics sectors, where the drive to make the idea of a circular economy a reality is declared by just over 60% of respondents. From their perspective, making green changes stay ahead of the competition, create and control industry trends and gain the trust of new groups of customers and investors.

What budget do medium and large companies allocate to sustainability? In which activities do they most often invest? Download the survey report and discover the latest trends in sustainability!

Action versus reality: the state of implementation of Agenda 2030 in the medium and large enterprise sector

Despite the implementation of further sustainable initiatives, significant the majority of companies surveyed are still a long way from achieving the goals of Agenda 2030 - considered the 'easiest' non-financial reporting target to implement has only been achieved by 20.5% respondents, while the 'most difficult' carbon neutrality target has only 15.7% respondents on track.

This state of affairs, as it were, forces companies to seek advisory support. Researched companies were almost unanimous in their desire to use an environmental consulting firm and to entrust it with strategic, management and operational tasks.

In the eyes of management: reducing waste and increasing efficiency by implementing sustainable solutions

Managers of large and medium-sized companies declared that the introduction of sustainable measures can benefit their companies in the following ways:

- reducing the amount of waste generated (and consequently reducing waste management costs),

- increase the efficiency of the company's operations,

- to meet the growing expectations of customers, financial institutions and investors,

- adapting to prevailing industry trends.

However, the authors of the padding emphasise that for real benefits to be realised, it is necessary to implement changes based on concrete data and measurements. Otherwise, companies risk misdirecting investments. Assessing the environmental performance of products, services and the organisation as a whole was declared by only 35.5% of the companies surveyed. Some of the companies surveyed stated that they did not have any useful data or research to create a strategy for their organisation's sustainability efforts.

These figures clearly indicate not only the need for research and development work, but also the need for ongoing cooperation with a consulting entity like Interzero as an experienced partner specialising in sustainability.

What support are entrepreneurs looking for? Criteria for selecting an environmental consultancy

Given the huge impact of sustainability activities on the perception of a company by all its stakeholders, companies seeking advisory support are guided by a number of concretised criteria.

- One of the most common criteria is the possibility of adapting the services offered to the specific nature of the business. Many entrepreneurs have experienced the difficulty or even impossibility of implementing off-the-shelf, unmodified solutions into their business models.

- Equally important is wide range consulting firm. Respondents particularly value availability of comprehensive, integrated environmental services and the opportunity to receive advice in other areas, not necessarily related to sustainability.

- A key criterion is also good reputation of the environmental consultancy.

As environmental consultants, we understand these expectations of entrepreneurs very well. At Interzero, we have been developing customised, integrated services for over 30 years in the field of environmental protection for companies of all sizes and from all sectors. We offer comprehensive environmental consultancy, training, audits, and we provide tailor-made solutions for sustainability, recycling, waste management and waste machinery. We support businesses in meeting their legal environmental obligations and in the implementation of a circular economy. We are already trusted by more than 9,500 entities - find out more about our environmental services and join the customers with whom we are pursuing a shared vision of a world without waste.

About the Interzero study

Six countries were analysed: Italy, Austria, Poland, Slovenia, Croatia and Serbia. The objectives of the study were: to understand and analyse market trends in sustainability and the circular economy, to explore potential barriers to the implementation of sustainable practices, to examine the main sustainability needs in the medium and large enterprise sector, to analyse the readiness of these enterprises to move towards more sustainable business models.

The data analysed in the course of the study came from company press releases, newspaper and magazine articles and sustainability reports, as well as from interviews conducted with top executives representing the companies under study

What do Poles know about the deposit and do we live in a clean environment? First such data

First steps towards cleanliness

From October 2025, a deposit system for selected beverage packaging will start operating in Poland. This is a response to the challenges related to littering public spaces and meeting EU requirements related to the level of collection of this waste. The new mechanism, included in the Packaging Management Act, is to cover plastic bottles up to 3 litres, aluminium cans up to 1 liter and reusable glass bottles up to 1.5 litres. The system, which aims to simplify segregation and reduce the amount of waste, will be based on a deposit - a fee that we will receive back after returning, for example, an aluminium can at an appropriate point.

Are Poles ready for change?

As shown in the second part of the report "In the traps of disposables - waiting for a deposit". , developed by Interzero, based on qualitative and quantitative research conducted by Opinia24, awareness of the system is at a different level. Every fourth Pole does not know at all that more returnable packaging will appear in our country any moment now, which will have to be returned to stores to get some of the money back. On the other hand, 77% of respondents know about its upcoming introduction, but only 32% correctly indicate that returning bottles does not require crushing, tearing off labels or caps. Such a lack of awareness may contribute to the spread of ignorance and misinformation about the new system and, as a result, affect the undermining of trust in the new mechanism.

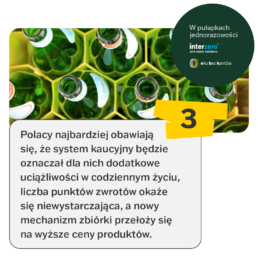

Fears and hopes

According to research, Poles expect the system to be simple and convenient, but at the same time they are afraid of its inconvenience. Nearly 42% of respondents are worried that the packaging will not be able to be returned to every store, and 41% are afraid of the long distances to the return points. Many unjustified doubts are also raised by the need to have a receipt (40%), which will not have to be kept to return cans and bottles. A key element will therefore be appropriate education that clearly explains the principles of the system and the availability of infrastructure on which the convenience of using the deposit system depends.

Deposit system in Europe

In many European Union countries , deposit systems have been operating successfully for years . For example, in Germany, the packaging return rate exceeds 98%, which shows how effective this form of selective collection and recycling of packaging can be. Key success factors include clear rules, the availability of return points (including machines) and an appropriately high deposit rate.

Why is it important?

The deposit system is not only a way to a cleaner environment, but also a possibility of better use of secondary raw materials. In times when the Single Use Plastic directive forces changes in the packaging economy, such solutions are necessary.

Read the full report

The second part of the report "In the traps of disposableness - waiting for a deposit". contains detailed analyses, data and recommendations. If you are interested in how the deposit system will affect our daily lives, or you want to check how you compare to the answers, be sure to read the whole thing on our website. Prepare for change and become part of the solution, not the problem!

Hairdressing and beauty salons must register with the BDO

With the new year, a new regulation came into force (Journal of Laws 2024, item 1644), in which 5 hazardous waste codes were removed from the list of waste codes exempt from the register, including 2 strictly related to the beauty industry. Unfortunately, the current exemption, which was eagerly used by entities generating small amounts of hazardous waste, will disappear. How to prepare for new obligations related to environmental protection?

Registration in BDO of hairdressing and beauty salons - Interzero support

Registration with BDO is a change for tens of thousands of hairdressers, beauticians and other service providers from the beauty industry who have so far produced< 200 kg/year of waste with code 15 01 10*. The BDO system is the Database on Products and Packaging and on Waste Management - a system that allows for electronic implementation of registration, record-keeping and reporting obligations in Poland. Are you not sure whether your business also has to register with BDO? Or maybe you do not want to deal with it and prefer that specialists take over the matter? On the BDO registration page for beauticians and hairdressers you will find a form - you can contact experts from our company who will take over this obligation. We act quickly because we have been doing it for years - and you gain valuable time that can be devoted to other areas of running a business. If you need more information about the BDO system, watch our free webinar about BDO .

Penalties for not registering with the BDO for beauticians and hairdressers - protect your business

Do you value your hard-earned money? This is another reason to make sure you are registered in the BDO. Let's start with the mildest penalty - that for not filing a BDO report. If an entity required to prepare an annual report on waste generated and waste management fails to file this report, it is subject to a fine - from PLN 20 to PLN 5,000. The penalty for not filing a BDO entry, on the other hand, ranges from PLN 5,000 to PLN 1,000,000. However, these are not the only concerns of entrepreneurs. Managing waste in a manner inconsistent with the information contained in the entry in the register is punishable by arrest or a fine - as is filing an application inconsistent with the actual state of affairs. It is also worth knowing what types of waste there are and which of them are generated by our company. Mixing hazardous waste of different types or mixing hazardous waste with non-hazardous waste is punishable by an administrative fine from PLN 5,000 to PLN 1,000,000.

Hazardous waste from beauty salons, hairdressers and the beauty industry - types and examples

This waste poses a particular threat to human and animal health and the natural environment. Their disposal may only take place in specially adapted plants and under restrictive control. Code 15 01 10* is packaging containing residues of hazardous substances or contaminated with them. Specific examples? Cans of paints, oxidants, brighteners, packaging of acetones, cleaners, packaging of products containing high concentrations of acids, or packaging of adhesives.

Are you looking for a company that will guide your business through the BDO entry? Fill out a simple form for beauty salons, hairdressers and the entire beauty industry - we will contact you!

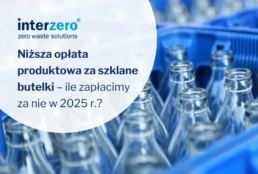

New product fee rates for glass packaging - significant reductions from 2025

New product fee rates for glass packaging - significant reductions from 2025

Glass bottles collected under the deposit system will be subject to a lower product fee than assumed. The new product fee rates result from the regulation of the Minister of Climate and Environment, which came into force at the beginning of 2025.

Lower product fee for glass bottles covered by the deposit system

On January 1, 2025, an amendment to the regulation of the Minister of Climate and Environment came into force, which significantly reduced the product fee rates for glass packaging collected under the deposit system. According to the new regulations, for each kilogram of reusable glass bottles, those introducing them will pay :

- PLN 0.01 (instead of PLN 0.10) in 2025,

- PLN 0.05 (instead of PLN 1) in 2026,

- PLN 0.25 (instead of PLN 5) in 2027 and subsequent years.

Let us recall that the previous regulations provided for uniform rates for all types of packaging covered by the deposit system. So what is the reason for this change?

Reduction of the product fee due to the higher weight of glass packaging

The amendment to the regulation was intended to make the product fee rates more realistic . As emphasized in the justification for the draft of the new regulation, the weight of a glass bottle is many times higher than the weight of a PET bottle or a can of identical capacity. Based on the data cited by the Ministry of Climate and Environment, the weights of half-liter packages covered by the deposit system are as follows:

- PET bottle - 13 g,

- drinks can - 14 g,

- glass bottle - 315 g.

This means that per 1 kilogram of packaging there are:

- 77 PET bottles,

- 71 cans,

- only 3 glass bottles.

In line with the principle that it is the number of packages that litters, not their weight , the product fee rates for glass packaging have been significantly reduced.

Discover Interzero's comprehensive services for deposit system participants >>

Environmental justification for reducing the product fee for glass packaging

The reduction of the product fee for glass packaging was dictated not only by economic issues, but also by ecological ones. The use of reusable packaging has a positive impact on the environment and brings us closer to the realisation of the idea of circular economy . The use of returnable glass bottles reduces the scale of production of new bottles, and thus reduces carbon dioxide emissions, electricity consumption and raw materials .

Maintaining the current, uniform product fee rates for all these types of packaging could cause those introducing them to abandon their use and replace "expensive" reusable glass with much "cheaper" single-use plastics. Giving up reusable glass bottles would be a step backwards, moving us further away from the transition to a circular economy.

See also:

- 9 months delay in the deposit system. What does this mean for the packaging industry?

- Sielaff Bottle Machines - the best machines for the deposit system

Sources:

- Regulation of the Minister of Climate and Environment of 24 December 2024 amending the regulation on product fee rates for individual types of packaging, https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20240001960/O/D20241960.pdf.

- https://legislacja.rcl.gov.pl/projekt/12389300/katalog/13079739#13079739

New product fee rates for glass packaging - significant reductions from 2025

Glass bottles collected under the deposit system will be subject to a lower product fee than assumed. The new product fee rates result from the regulation of the Minister of Climate and Environment, which came into force at the beginning of 2025.

Lower product fee for glass bottles covered by the deposit system

On January 1, 2025, an amendment to the regulation of the Minister of Climate and Environment came into force, which significantly reduced the product fee rates for glass packaging collected under the deposit system. According to the new regulations, for each kilogram of reusable glass bottles, those introducing them will pay :

- PLN 0.01 (instead of PLN 0.10) in 2025,

- PLN 0.05 (instead of PLN 1) in 2026,

- PLN 0.25 (instead of PLN 5) in 2027 and subsequent years.

Let us recall that the previous regulations provided for uniform rates for all types of packaging covered by the deposit system. So what is the reason for this change?

Reduction of the product fee due to the higher weight of glass packaging

The amendment to the regulation was intended to make the product fee rates more realistic . As emphasized in the justification for the draft of the new regulation, the weight of a glass bottle is many times higher than the weight of a PET bottle or a can of identical capacity. Based on the data cited by the Ministry of Climate and Environment, the weights of half-liter packages covered by the deposit system are as follows:

- PET bottle - 13 g,

- drinks can - 14 g,

- glass bottle - 315 g.

This means that per 1 kilogram of packaging there are:

- 77 PET bottles,

- 71 cans,

- only 3 glass bottles.

In line with the principle that it is the number of packages that litters, not their weight , the product fee rates for glass packaging have been significantly reduced.

Discover Interzero's comprehensive services for deposit system participants >>

Environmental justification for reducing the product fee for glass packaging

The reduction of the product fee for glass packaging was dictated not only by economic issues, but also by ecological ones. The use of reusable packaging has a positive impact on the environment and brings us closer to the realisation of the idea of circular economy . The use of returnable glass bottles reduces the scale of production of new bottles, and thus reduces carbon dioxide emissions, electricity consumption and raw materials .

Maintaining the current, uniform product fee rates for all these types of packaging could cause those introducing them to abandon their use and replace "expensive" reusable glass with much "cheaper" single-use plastics. Giving up reusable glass bottles would be a step backwards, moving us further away from the transition to a circular economy.

See also:

- 9 months delay in the deposit system. What does this mean for the packaging industry?

- Sielaff Bottle Machines - the best machines for the deposit system

Sources:

- Regulation of the Minister of Climate and Environment of 24 December 2024 amending the regulation on product fee rates for individual types of packaging, https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20240001960/O/D20241960.pdf.

- https://legislacja.rcl.gov.pl/projekt/12389300/katalog/13079739#13079739

From 2025 obligation to selectively collect textile waste. Where to throw away old clothes and shoes?

From 2025 obligation to selectively collect textile waste. Where to throw away old clothes and shoes?

From 1 January 2025, textile waste can no longer be disposed of as mixed waste. At the beginning of the year, an amendment to the Act on Maintaining Cleanliness and Order in Municipalities and certain other acts came into force, which obliges all municipalities to conduct selective collection of textile waste.

Selective collection of textile waste on the shoulders of municipalities

According to the provisions of the amendment, from 1 January 2025, each commune is obliged to organise selective collection of textile waste , which includes, among others, used clothing and footwear, home textiles (bedding, curtains) and other fabric products. The minimum that local governments must ensure is the possibility of returning all textile waste to the local PSZOK .

Currently, there are no plans to introduce an additional, sixth container exclusively for textile waste or to oblige municipalities to collect this fraction of waste from properties. However, municipalities have the freedom to organise additional methods of collecting textile waste e.g. collecting it directly from households or creating additional collection points. Częstochowa has recently been testing a similar solution, which allows its residents to return textile waste free of charge after prior telephone appointment.

Textile waste under the EU's microscope

The introduction of the obligation to selectively collect textile waste results from the transposition into Polish law of the provisions of Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives. Article 11 paragraph 1 of the Directive obliges all EU Member States to conduct selective collection of at least the following fractions: paper, metal, plastics, glass and textiles. This last fraction is mandatory collected throughout the EU from 1 January 2025.

Let us recall that the European Union is still working on implementing legislation to increase the effectiveness of textile waste collection and impose additional obligations on textile producers, known as the extended producer responsibility system. Under the provisions of the EPR, those introducing textiles are to be charged with the costs related to the collection, segregation and recycling of waste generated from them.

Penalties for incorrect segregation of textile waste

Selective collection of textile waste means new obligations not only for municipalities, but also for their residents. From the new year , it is forbidden to throw textiles into the mixed waste bin . Fines for failure to comply with the new rules or for incorrect waste sorting can range from 200 to 400% of the basic waste collection fee. It should be emphasised that these penalties are not one-off - if residents of the property continue to fail to comply with the statutory obligations, financial penalties may also be charged in the following months.

The mechanism for calculating such punitive fees is already well known to us - similar consequences will also be faced by us for incorrect sorting of other waste fractions for which there is an obligation to selectively collect (glass, metal and plastics, paper, bio-waste). Why are we reminding you of this? Well, the study we conducted in 2023 showed that only 62% of Poles segregate waste into all the required fractions, and even fewer, 43%, declare that they can do it correctly. You will find more conclusions in the report from the research We are getting into trouble .

Where to throw away old clothes and shoes?

Contrary to appearances, since January we are not obliged to return all used textiles to PSZOK. Used textiles in good condition can be donated to charities (e.g. PCK, Caritas, single mothers' homes, homeless shelters) or thrown into a used clothing container .

Textile manufacturers also offer alternative collection points for textiles , giving consumers the opportunity to return old clothes or shoes to their stores. In most cases, these can be products of any brand, which will then be recycled, upcycled or reintroduced to second-hand stores.

As representatives of the waste and recycling industry, we strongly encourage you to act in the spirit of our idea Together for a World Without Waste, which involves not only proper handling of textile waste, but also preventing its generation. How to do it? Discover 5 ways for ecological fashion and a sustainable wardrobe .

Changes in BDO - new regulations for 2025

Changes in BDO - new regulations for 2025

From January 2025, important changes to waste management rules and the functioning of the BDO system will come into force. Their goal is to increase control over waste management, further increase the levels and effectiveness of recycling, and protect the environment. See what will change in BDO in 2025 and check if the new regulations will also apply to your company!

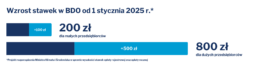

BDO fees up in 2025 - 100% and 166% increase

The change that will affect all entrepreneurs entered in the BDO register is the increase in the annual and registration fee . It is dictated by, among other things, the growing costs of maintaining, running and developing BDO.

From 2025 BDO fee rates will be:

- PLN 200 for micro-entrepreneurs (increase from PLN 100),

- PLN 800 for other entrepreneurs (increase from PLN 300).

Let us remind you that the deadline for paying the annual fee for a given calendar year expires at the end of February - in 2025 it will be February 28. The annual fee must be paid in the new amount by that date.

New regulations for hazardous waste management in 2025

From 2025 an obligation to keep records of all hazardous waste generated by entrepreneurs will be introduced. This means that the previously applicable exemptions will disappear , which were eagerly used by entities generating small amounts of hazardous waste, including beauticians and hairdressers. Entrepreneurs running beauty and hairdressing salons can order registration in BDO Interzero - quickly, conveniently and 100% online.

You can read more about the new obligations of the beauty industry in the article: Beauty and hairdressing salons with the obligation to register with the BDO>>.

The obligation to record will cover hazardous waste with the following codes:

- 3 02 08* Other engine, gear and lubricating oils,

- 15 01 10* Packaging containing residues of or contaminated with hazardous substances,

- ex 15 01 11* Metal packaging containing hazardous porous reinforcements other than those of asbestos, including empty pressure containers,

- 16 02 13* Discarded equipment containing hazardous components other than those mentioned in 16 02 09 to 16 02 12,

- 16 06 03* Batteries containing mercury.

Do you produce such hazardous waste? Check if you need to register your company with BDO in 2025!

Further changes to the obligation to segregate construction and demolition waste in 2025

From January 2025, the obligation to segregate construction and demolition waste into 6 fractions will come into force . The latest change, however, is the departure from the requirement to ensure segregation of R&D waste at the place of its generation - . the entrepreneur will be able to transfer the obligation to segregate it to another entity with appropriate permits and entries in the BDO, provided that an appropriate agreement is signed.

In the previous version of the regulations, the legislator obliged every producer of construction and demolition waste to segregate it at source. As a result of the amendment to the Waste Act, the possibility of segregating waste outside the place of its generation was introduced, but it did not release the entrepreneur from the responsibility for ensuring the implementation of this obligation.

Learn about the new rules for managing construction and demolition waste in 2025.

Postponement of the launch of the confirmation module in BDO

In 2025. it will not be possible to issue DPR and EDPR documents in the BDO system . The introduction of the Confirmation Module, which was to enable the digital generation of these documents, has been postponed until 1 January 2027. From that date, entrepreneurs will be able to electronically issue DPRs and EDPRs for packaging and products, as well as certificates for electrical and electronic equipment and batteries and accumulators.

In 2025-2026, recycling confirmation documents will continue to be issued in paper form .

Increase in financial outlays for BDO in 2025-2034

From 2025, the limits for spending funds from the National Fund for Environmental Protection and Water Management for purposes related to the operation of BDO will be raised . This is to ensure further, trouble-free access to BDO, as well as to maintain the current level of cybersecurity and finance the development of the system.

Moreover, revenues from registration fees and annual fees for entry in the BDO will be a direct income of the National Fund for Environmental Protection and Water Management.